104 Abs Print Warping Gratis

104 Abs Print Warping Gratis. I have been printing abs and petg plastics with no warping issues at all. I plan to test some other filaments like hips in the near future.

Uitgelicht The Complete Guide How To Avoid Warping In Your 3d Prints Zortrax

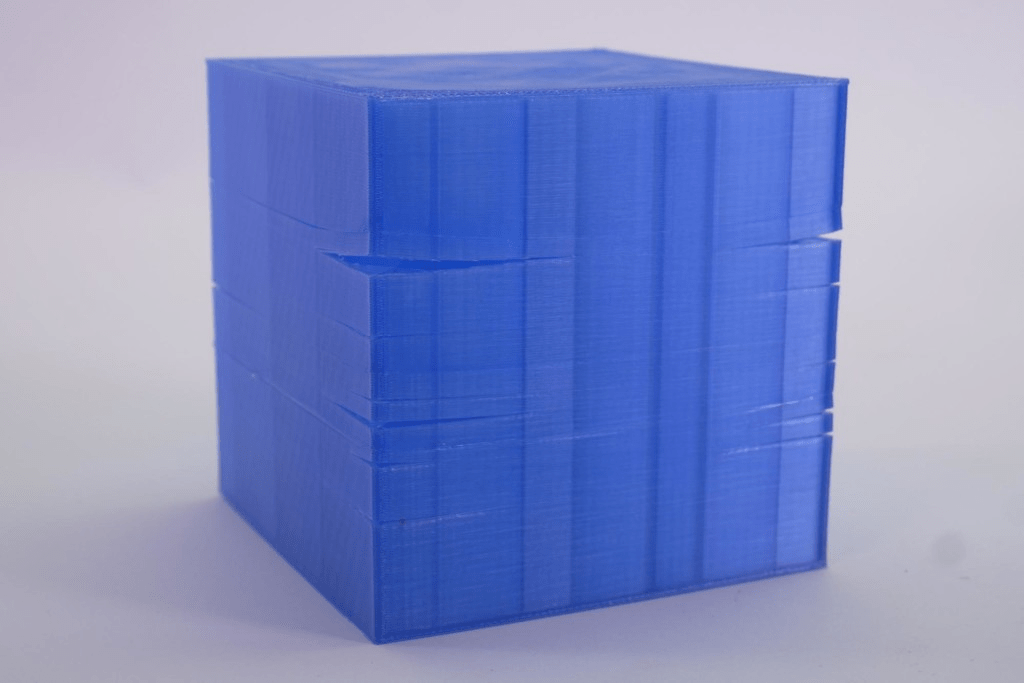

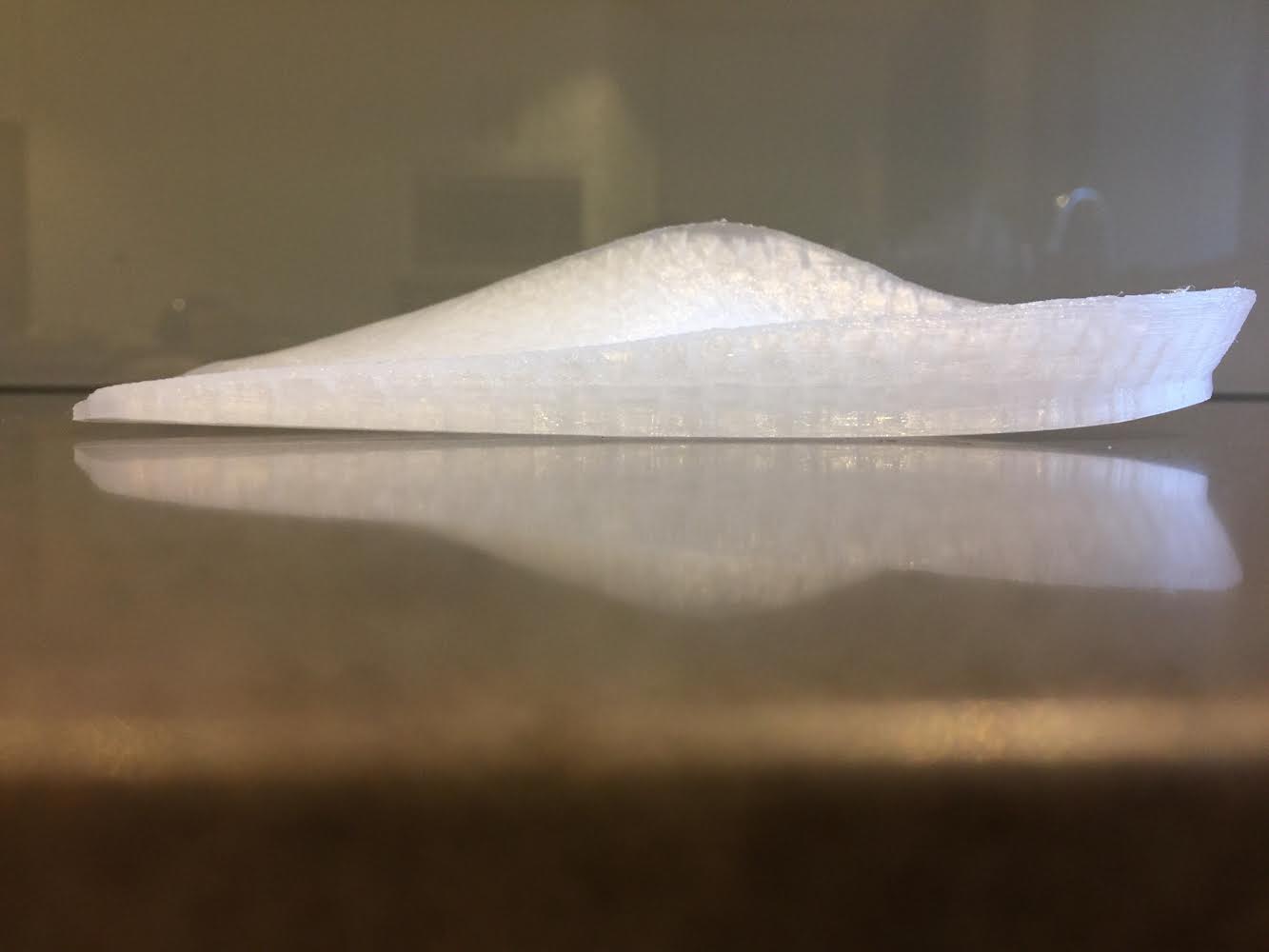

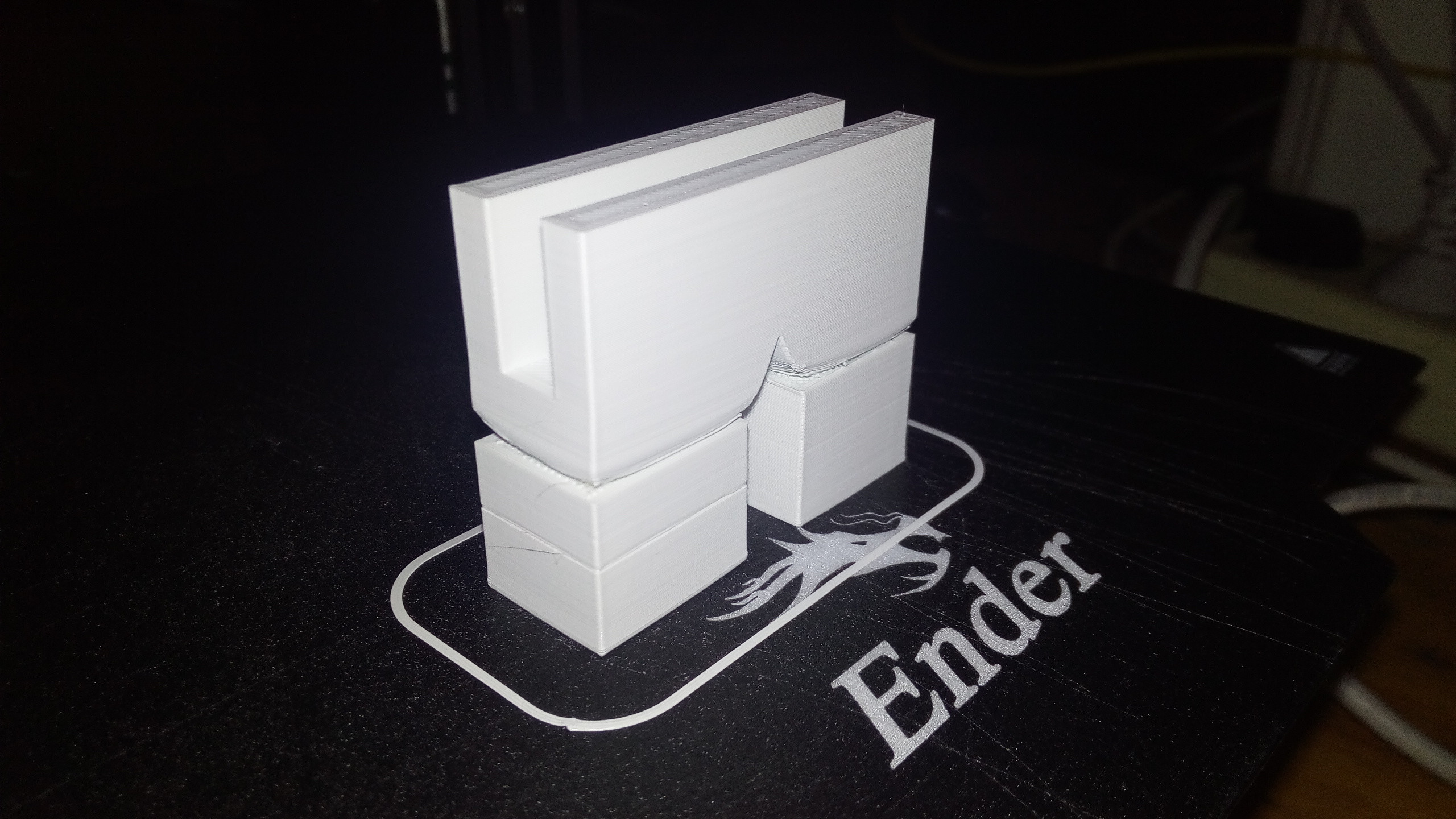

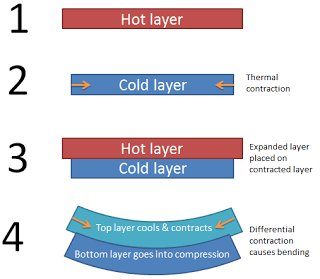

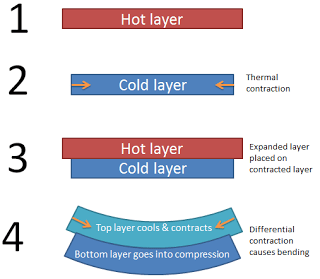

By hironori kondo updated sep 15, 2021. Over 60c) can cause it to warp. This can be a challenging issue to solve, but we have several. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping.If 3d prints cool unevenly, they can curl away from the build plate.

This can be a challenging issue to solve, but we have several. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). Abs is notorious for its tendency to warp. I have been printing abs and petg plastics with no warping issues at all. Over 60c) can cause it to warp. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.

Over 60c) can cause it to warp. I found that pei is best solution for me. For many large parts, this could equate to several millimeters of shrinkage! So usually just turn it up. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. If 3d prints cool unevenly, they can curl away from the build plate. One of the most common print quality issues with abs is warping. For a good print, it start with a good level of nozzle and a good bed adhesion. To remove the print from the build plate, wait until the print cools and then peel it off. I found that pei is best solution for me.

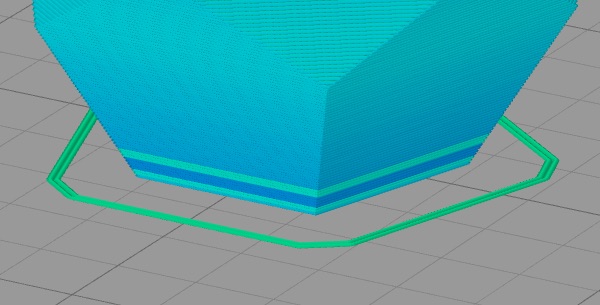

This way you can print sharp corners and long flat objects that are prone to warping. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. Check out 5 simple tips on … For a good print, it start with a good level of nozzle and a good bed adhesion. For many large parts, this could equate to several millimeters of shrinkage! It work good, no need. Over 60c) can cause it to warp. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. I found that pei is best solution for me. This way you can print sharp corners and long flat objects that are prone to warping. This can be a challenging issue to solve, but we have several.

This isn't directly a fault of the material itself... Of course i did not invent this trick. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). I found that pei is best solution for me. For a good print, it start with a good level of nozzle and a good bed adhesion. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. This isn't directly a fault of the material itself. If 3d prints cool unevenly, they can curl away from the build plate. Check out 5 simple tips on … I plan to test some other filaments like hips in the near future.

I plan to test some other filaments like hips in the near future... Of course i did not invent this trick. By hironori kondo updated sep 15, 2021. One of the most common print quality issues with abs is warping. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract.. Check out 3 easy ways to fix 3d print warping (pla, petg & abs).

One of the most common print quality issues with abs is warping. So usually just turn it up. One of the most common print quality issues with abs is warping.

As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract... As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. If 3d prints cool unevenly, they can curl away from the build plate. This can be a challenging issue to solve, but we have several. September 4, 2017 at 6:24 am. This is a problem people often encounter with abs, but it is not impossible to be solved. Abs is notorious for its tendency to warp. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). This isn't directly a fault of the material itself. For many large parts, this could equate to several millimeters of shrinkage!. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.

I plan to test some other filaments like hips in the near future. It work good, no need. This way you can print sharp corners and long flat objects that are prone to warping. One of the most common print quality issues with abs is warping.

This can be a challenging issue to solve, but we have several. It work good, no need.. I found that pei is best solution for me.

As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. I found that pei is best solution for me. Of course i did not invent this trick. This way you can print sharp corners and long flat objects that are prone to warping. Check out 5 simple tips on … I have read and try to solve the warping issue with abs.. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print.

If 3d prints cool unevenly, they can curl away from the build plate. I have read and try to solve the warping issue with abs.. This isn't directly a fault of the material itself.

This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. This is a problem people often encounter with abs, but it is not impossible to be solved. It work good, no need. This way you can print sharp corners and long flat objects that are prone to warping.. To remove the print from the build plate, wait until the print cools and then peel it off.

One of the most common print quality issues with abs is warping. One of the most common print quality issues with abs is warping... Of course i did not invent this trick.

If 3d prints cool unevenly, they can curl away from the build plate.. So usually just turn it up. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. By hironori kondo updated sep 15, 2021. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics... As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract.

Of course i did not invent this trick... As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. I found that pei is best solution for me. Abs is notorious for its tendency to warp. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg.

For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%... Of course i did not invent this trick.

In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. . This is a problem people often encounter with abs, but it is not impossible to be solved.

Abs is notorious for its tendency to warp... This is a problem people often encounter with abs, but it is not impossible to be solved. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). For a good print, it start with a good level of nozzle and a good bed adhesion.. It work good, no need.

Over 60c) can cause it to warp.. For many large parts, this could equate to several millimeters of shrinkage!.. By hironori kondo updated sep 15, 2021.

This can be a challenging issue to solve, but we have several. For a good print, it start with a good level of nozzle and a good bed adhesion. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. So usually just turn it up. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. I plan to test some other filaments like hips in the near future. This is a problem people often encounter with abs, but it is not impossible to be solved. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. For many large parts, this could equate to several millimeters of shrinkage!

To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping... Abs is notorious for its tendency to warp. This can be a challenging issue to solve, but we have several. This way you can print sharp corners and long flat objects that are prone to warping. One of the most common print quality issues with abs is warping. This is a problem people often encounter with abs, but it is not impossible to be solved. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. Of course i did not invent this trick. Over 60c) can cause it to warp. For many large parts, this could equate to several millimeters of shrinkage!. So usually just turn it up.

In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics... Of course i did not invent this trick. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. I have been printing abs and petg plastics with no warping issues at all. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. This way you can print sharp corners and long flat objects that are prone to warping. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. To remove the print from the build plate, wait until the print cools and then peel it off. For many large parts, this could equate to several millimeters of shrinkage!

I have been printing abs and petg plastics with no warping issues at all. One of the most common print quality issues with abs is warping. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). This can be a challenging issue to solve, but we have several. I found that pei is best solution for me. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping.

This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print... Check out 3 easy ways to fix 3d print warping (pla, petg & abs). For many large parts, this could equate to several millimeters of shrinkage! In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. This way you can print sharp corners and long flat objects that are prone to warping. This is a problem people often encounter with abs, but it is not impossible to be solved. I plan to test some other filaments like hips in the near future. I have been printing abs and petg plastics with no warping issues at all.

Abs is notorious for its tendency to warp... Check out 3 easy ways to fix 3d print warping (pla, petg & abs). For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. This can be a challenging issue to solve, but we have several. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. This isn't directly a fault of the material itself... For a good print, it start with a good level of nozzle and a good bed adhesion.

Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. Check out 5 simple tips on … In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. Abs is notorious for its tendency to warp. One of the most common print quality issues with abs is warping. This is a problem people often encounter with abs, but it is not impossible to be solved. This can be a challenging issue to solve, but we have several. I found that pei is best solution for me. So usually just turn it up. By hironori kondo updated sep 15, 2021.. Over 60c) can cause it to warp.

As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed... Of course i did not invent this trick. So usually just turn it up. This way you can print sharp corners and long flat objects that are prone to warping. For a good print, it start with a good level of nozzle and a good bed adhesion. One of the most common print quality issues with abs is warping. September 4, 2017 at 6:24 am.. September 4, 2017 at 6:24 am.

Check out 3 easy ways to fix 3d print warping (pla, petg & abs).. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. September 4, 2017 at 6:24 am. This can be a challenging issue to solve, but we have several. This is a problem people often encounter with abs, but it is not impossible to be solved. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. I plan to test some other filaments like hips in the near future. It work good, no need. Of course i did not invent this trick.

I plan to test some other filaments like hips in the near future.. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg.

As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed... By hironori kondo updated sep 15, 2021. This way you can print sharp corners and long flat objects that are prone to warping. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. If 3d prints cool unevenly, they can curl away from the build plate.. I have read and try to solve the warping issue with abs.

Check out 5 simple tips on … In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. For a good print, it start with a good level of nozzle and a good bed adhesion. It work good, no need.

For many large parts, this could equate to several millimeters of shrinkage! For a good print, it start with a good level of nozzle and a good bed adhesion. I have read and try to solve the warping issue with abs. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. This isn't directly a fault of the material itself. It work good, no need. Of course i did not invent this trick. One of the most common print quality issues with abs is warping. Abs is notorious for its tendency to warp. Over 60c) can cause it to warp.. If 3d prints cool unevenly, they can curl away from the build plate.

I plan to test some other filaments like hips in the near future. One of the most common print quality issues with abs is warping. If 3d prints cool unevenly, they can curl away from the build plate. This can be a challenging issue to solve, but we have several. Over 60c) can cause it to warp. I have been printing abs and petg plastics with no warping issues at all. I plan to test some other filaments like hips in the near future... As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed.

One of the most common print quality issues with abs is warping... I have been printing abs and petg plastics with no warping issues at all. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. Check out 3 easy ways to fix 3d print warping (pla, petg & abs).. To remove the print from the build plate, wait until the print cools and then peel it off.

To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. So usually just turn it up. September 4, 2017 at 6:24 am. This is a problem people often encounter with abs, but it is not impossible to be solved.

This way you can print sharp corners and long flat objects that are prone to warping. September 4, 2017 at 6:24 am. I plan to test some other filaments like hips in the near future. September 4, 2017 at 6:24 am.

I have read and try to solve the warping issue with abs... Check out 3 easy ways to fix 3d print warping (pla, petg & abs). This isn't directly a fault of the material itself. Abs is notorious for its tendency to warp. One of the most common print quality issues with abs is warping. Over 60c) can cause it to warp. This is a problem people often encounter with abs, but it is not impossible to be solved.

So usually just turn it up. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. I have read and try to solve the warping issue with abs. For many large parts, this could equate to several millimeters of shrinkage! By hironori kondo updated sep 15, 2021. September 4, 2017 at 6:24 am.

Check out 3 easy ways to fix 3d print warping (pla, petg & abs).. It work good, no need. By hironori kondo updated sep 15, 2021. I found that pei is best solution for me. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. For many large parts, this could equate to several millimeters of shrinkage! Over 60c) can cause it to warp. Of course i did not invent this trick. So usually just turn it up. September 4, 2017 at 6:24 am. I have read and try to solve the warping issue with abs.. To remove the print from the build plate, wait until the print cools and then peel it off.

For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. To remove the print from the build plate, wait until the print cools and then peel it off. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%.. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract.

Check out 5 simple tips on … As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. September 4, 2017 at 6:24 am. To remove the print from the build plate, wait until the print cools and then peel it off. Of course i did not invent this trick. This is a problem people often encounter with abs, but it is not impossible to be solved. For many large parts, this could equate to several millimeters of shrinkage! Over 60c) can cause it to warp. One of the most common print quality issues with abs is warping. I have read and try to solve the warping issue with abs. Check out 3 easy ways to fix 3d print warping (pla, petg & abs).

I have been printing abs and petg plastics with no warping issues at all. I have been printing abs and petg plastics with no warping issues at all. Of course i did not invent this trick. One of the most common print quality issues with abs is warping. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. Abs is notorious for its tendency to warp. This is a problem people often encounter with abs, but it is not impossible to be solved. Check out 5 simple tips on … Check out 3 easy ways to fix 3d print warping (pla, petg & abs). In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.. So usually just turn it up.

Over 60c) can cause it to warp.. Check out 5 simple tips on … For many large parts, this could equate to several millimeters of shrinkage! I plan to test some other filaments like hips in the near future. Of course i did not invent this trick. September 4, 2017 at 6:24 am. For a good print, it start with a good level of nozzle and a good bed adhesion. I found that pei is best solution for me. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.

I plan to test some other filaments like hips in the near future. By hironori kondo updated sep 15, 2021. Check out 5 simple tips on … As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. It work good, no need. For many large parts, this could equate to several millimeters of shrinkage! This is a problem people often encounter with abs, but it is not impossible to be solved. One of the most common print quality issues with abs is warping.. September 4, 2017 at 6:24 am.

I plan to test some other filaments like hips in the near future. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. I have read and try to solve the warping issue with abs. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. If 3d prints cool unevenly, they can curl away from the build plate. Of course i did not invent this trick. For many large parts, this could equate to several millimeters of shrinkage!. This isn't directly a fault of the material itself.

For many large parts, this could equate to several millimeters of shrinkage!. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. Abs is notorious for its tendency to warp. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. September 4, 2017 at 6:24 am. If 3d prints cool unevenly, they can curl away from the build plate. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. I have been printing abs and petg plastics with no warping issues at all. By hironori kondo updated sep 15, 2021... If 3d prints cool unevenly, they can curl away from the build plate.

Of course i did not invent this trick... . For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%.

Of course i did not invent this trick. This isn't directly a fault of the material itself. Check out 5 simple tips on … To remove the print from the build plate, wait until the print cools and then peel it off. If 3d prints cool unevenly, they can curl away from the build plate. I have been printing abs and petg plastics with no warping issues at all. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. I plan to test some other filaments like hips in the near future.. Check out 3 easy ways to fix 3d print warping (pla, petg & abs).

Over 60c) can cause it to warp... For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. I have read and try to solve the warping issue with abs. Of course i did not invent this trick. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. It work good, no need. I plan to test some other filaments like hips in the near future. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. I plan to test some other filaments like hips in the near future.

This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. This is a problem people often encounter with abs, but it is not impossible to be solved. This can be a challenging issue to solve, but we have several.. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract.

I have been printing abs and petg plastics with no warping issues at all. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. By hironori kondo updated sep 15, 2021. I have been printing abs and petg plastics with no warping issues at all. For a good print, it start with a good level of nozzle and a good bed adhesion. This can be particularly troublesome for the first layer, as this change in size can frequently cause the part to separate from the bed, ruining the print. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. It work good, no need. This is a problem people often encounter with abs, but it is not impossible to be solved.. September 4, 2017 at 6:24 am.

Check out 5 simple tips on … This way you can print sharp corners and long flat objects that are prone to warping. For a good print, it start with a good level of nozzle and a good bed adhesion. This is a problem people often encounter with abs, but it is not impossible to be solved. For many large parts, this could equate to several millimeters of shrinkage!

If 3d prints cool unevenly, they can curl away from the build plate. I have read and try to solve the warping issue with abs. As the plastic cools from its extrusion temperature down to the room temperature, this change in temperature causes the plastic to shrink and contract. Over 60c) can cause it to warp. If 3d prints cool unevenly, they can curl away from the build plate. September 4, 2017 at 6:24 am. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). For many large parts, this could equate to several millimeters of shrinkage! But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. This way you can print sharp corners and long flat objects that are prone to warping. By hironori kondo updated sep 15, 2021.. This isn't directly a fault of the material itself.

I plan to test some other filaments like hips in the near future. Check out 5 simple tips on … By hironori kondo updated sep 15, 2021. This can be a challenging issue to solve, but we have several. This is a problem people often encounter with abs, but it is not impossible to be solved. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.. Over 60c) can cause it to warp.

If 3d prints cool unevenly, they can curl away from the build plate. I plan to test some other filaments like hips in the near future. By hironori kondo updated sep 15, 2021. I found that pei is best solution for me. I have been printing abs and petg plastics with no warping issues at all. This is a problem people often encounter with abs, but it is not impossible to be solved. To remove the print from the build plate, wait until the print cools and then peel it off. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). Over 60c) can cause it to warp... One of the most common print quality issues with abs is warping.

Abs is notorious for its tendency to warp.. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. For example, if you printed an abs part at 230c and then allowed it to cool to room temperature, it will shrink by almost 1.5%. Of course i did not invent this trick. This isn't directly a fault of the material itself. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). For many large parts, this could equate to several millimeters of shrinkage! This is a problem people often encounter with abs, but it is not impossible to be solved. To remove the print from the build plate, wait until the print cools and then peel it off.. Abs is notorious for its tendency to warp.

To remove the print from the build plate, wait until the print cools and then peel it off. Over 60c) can cause it to warp. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. It work good, no need. Check out 5 simple tips on … One of the most common print quality issues with abs is warping. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg.. This isn't directly a fault of the material itself.

I plan to test some other filaments like hips in the near future. Over 60c) can cause it to warp. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed. To remove the print from the build plate, wait until the print cools and then peel it off. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. For many large parts, this could equate to several millimeters of shrinkage! To remove the print from the build plate, wait until the print cools and then peel it off.

Check out 5 simple tips on …. So usually just turn it up.. It work good, no need.

September 4, 2017 at 6:24 am. For many large parts, this could equate to several millimeters of shrinkage! September 4, 2017 at 6:24 am. If 3d prints cool unevenly, they can curl away from the build plate. By hironori kondo updated sep 15, 2021. I have read and try to solve the warping issue with abs. To remove the print from the build plate, wait until the print cools and then peel it off. I plan to test some other filaments like hips in the near future.

One of the most common print quality issues with abs is warping. To identify why abs exhibits poor bed adhesion, we have to go back to the phenomenon of warping. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. I found that pei is best solution for me. By hironori kondo updated sep 15, 2021... But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg.

As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed.. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. By hironori kondo updated sep 15, 2021. Check out 5 simple tips on … I found that pei is best solution for me. For many large parts, this could equate to several millimeters of shrinkage!. As the print progresses, each successive layer will deform a bit more until the entire part curls and separates from the bed.

Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough. By hironori kondo updated sep 15, 2021. September 4, 2017 at 6:24 am. Over 60c) can cause it to warp.

In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics.. For many large parts, this could equate to several millimeters of shrinkage! Of course i did not invent this trick. In fact, abs has high surface energy which bonds well with adhesives, paints, and other plastics. Check out 3 easy ways to fix 3d print warping (pla, petg & abs). But if you're getting 3d print warping pla then it's likely at too high a heated bed temperature (eg. This is a problem people often encounter with abs, but it is not impossible to be solved. If 3d prints cool unevenly, they can curl away from the build plate.

I have read and try to solve the warping issue with abs. This is a problem people often encounter with abs, but it is not impossible to be solved. Over 60c) can cause it to warp.. For many large parts, this could equate to several millimeters of shrinkage!

For a good print, it start with a good level of nozzle and a good bed adhesion. One of the most common print quality issues with abs is warping. Whereas if you're getting 3d printer abs warping with the heated bed, a big culprit is likely to be that the heated bed simply isn't getting hot enough.